F-35 Joint Strike Fighter: Events & Contracts 2007

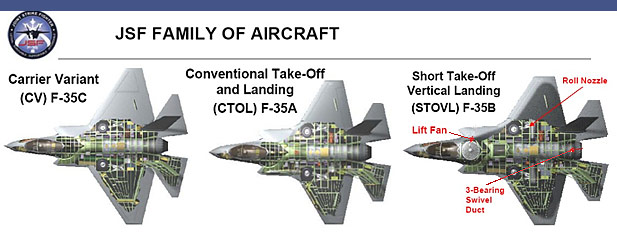

F-35 Variants: The F-35 Lightning II is a major multinational program which is intended to produce an "affordably stealthy" multi-role strike fighter that will have three variants

The F-35A conventional version for the US Air Force et. al.; the F-35B Short Take-Off, Vertical Landing for the US Marines, British Royal Navy, et. al.; and the F-35C conventional carrier-launched version for the US Navy. The aircraft is named after Lockheed's famous WW2 P-38 Lightning, and the Mach 2, stacked-engine English Electric (now BAE) Lightning jet. System development partners included The USA & Britain (Tier 1), Italy and the Netherlands (Tier 2), and Australia, Canada, Denmark, Norway and Turkey (Tier 3). Now the challenge is agreeing on production phase membership and arrangements, to be followed by initial purchase commitments around 2008-2009.

This updated article has expanded to feature more detail regarding the $300 billion F-35 program, including other contracts as well as notable events. As a result of reader feedback, we'll make the new material more visible by putting it in green type. Recent news includes program cost changes described in the Pentagon's latest Selected Acquisition Report; and official US government reports evaluating the F-35's dual engine program, its overall acquisition strategy, and overall US TacAir fighter procurement plans that GAO predicts will be "unexecutable"....

F-35 Program: Background & Structure

F-16B & X-35

(click to view full)As noted at the beginning of this article, the F-35 is designed as an 'affordable stealth' counterpart to the F-22 Raptor air dominance fighter, one that can share "first day of the war" duties against defended targets but can't perform air-air or air-ground missions to the same standard. Its air-air combat flight benchmarks are only on par with the F-16, it has a single engine instead of twin thrust-vectoring F119s, and stealth that is less than the F-22A's but still represents an improvement over existing 'teen series' fighters and even 4th generation options like the Eurofighter.

The Lightning II's advanced APG-81 AESA radar offers it strong simultaneous air-air and air-ground capabilities, and it also shares a design advance with the F-22 in having sensors of various types embedded all around the airframe. These electronics are connected to a lot of computing power in order to create single-picture "sensor fusion" that lets the pilot see what's going on in one picture and just fly the plane, rather than pushing buttons and trying to figure it all out. Finally, the F-35 has a large number of design features designed to simplify maintenance and keep life cycle costs down. See references in "Additional Readings & Sources," below, for more detailed information.

The F-35 will also have interchangeable engine options, at least for now. Pratt & Whitney's F135 powers the current test aircraft, and a special version with add-ons will also power the vertical-landing F-35B. GE and Rolls Royce are working on the F136, however, which can fit into any F-35 without modifications and also has a special version for the F-35B. Customers will be able to select which engine they want installed on their fighters - and they will also have a choice of fighter models:

From Top: F-35A, C, B

(click to view larger)The F-35A is the basic air force version, and is expected to be the predominant export type. Its main difference from other versions is an internal 25mm cannon rather than relying on a stealth-friendly gun pod option; the Air Force removed guns from some of its planes back in the 1960s, and didn't enjoy the resulting experiences.

The F-35B STOVL will serve the US Marines, Royal Navy, other navies with LHDs or small carriers, and militaries looking for an "expeditionary airplane" that can take off in short distances and land vertically. To achieve this, it has a large fan behind the cockpit and nozzles that go our to the wing undersides. In return for these capabilities, it gives up some range, some bomb load, some structural strength (7g maneuvers maximum instead of 9g), and the internal gun. For all this, it will be much more capable and also safer than the AV-8B Harrier II - but it will also be the most challenging version to design, and probably the most expensive to buy.

The F-35C carrier-based fighter has enlarged wings and horizontal stabilizers, structural strengthening, and an arrester hook to help it deal with the controlled crashes of carrier landings. It will have slightly more range than other versions, but the Navy gave up the internal gun. It is expected to be the US Navy's high-end fighter as well as a strike aircraft, which may be challenging given the aircraft's design goal of merely equaling the F-16.

Lightning II official rollout

(click to view full)The first test aircraft, an F-35A model AA-1, had its formal rollout on July 7, 2006. The F-35B STOVL's forced redesign for weight reasons has led to F-35 AA-1 being a unique airframe used to validate design, manufacturing, assembly and test processes. The first optimized-airframe F-35B STOVL is being assembled by Lockheed Martin, Northrop Grumman, and BAE Systems; it is scheduled to fly in February 2008. The first optimized-airframe F-35A will follow in August 2008, and the first F-35C carrier variant is scheduled for flight in January 2009. A total of 23 test aircraft are scheduled to be built for various purposes (15 flight, 7 non-flight, 1 radar signature) - see Flight International article for details re: "Option 9".

The JSF program is 'tiered,' with 4 possible levels of participation based on admission levels and funding commitments for the System Design & Development (SDD) phase. Note that all totals below are in US dollar equivalents:

Tier 1 Partners: The USA+ (majority commitment), Britain+ ($2 billion)

Tier 2 Partners: Italy+ ($1 billion); The Netherlands+ ($800 million)

Tier 3 Partners: Australia+ ($150M), Canada+ ($150M), Denmark+ ($125M), Norway+ ($125M), Turkey+ ($175M)

Observer status: Israel ($35M), Singapore.

+ = signed the Phase 3 Production MoU

At present, main production and final assembly is slated to take place in Lockheed's Fort Worth, TX plant. Italy has expressed an interest in a Lockheed-Martin Final Assembly and Check Out (FACO) plant for European orders, The Netherlands wants to be a center for engine heavy maintenance, and Britain is examining a FACO of its own. The issue of the JSF's security-sensitive stealth enhancing coatings and how their application will be managed remains to be decided.

BAE Systems is also deriving substantial benefits from Britain's Tier 1 partner status; they will be responsible for the design, manufacture and assembly of the F-35 JSF aft fuselage and empennage (vertical and horizontal tails), and are also involved in other areas including the crew escape system, fuel system, life support system and proactive aircraft diagnostics system integration.

Northrop Grumman is responsible for the F-35's important 'center barrel' section.

F-35 Program: Events & Developments

Gentlemen, start your....

(click to view full)During the FY 2006 period, the JSF program saw 4 major developments. The first and most obvious was the formal rollout of the first test plane on July 7, 2006, and the bestowal of its official name "F-35 Lightning II". The second was a set of production phase agreements with Australia (Tier 3), Britain (Tier 1), Canada (Tier 3), and The Netherlands (Tier 2), with more to follow in early 2007.

The other developments may have passed unnoticed unless one was looking. For instance, it was revealed that the F/A-22 Raptor and F-35 Joint Strike Fighter (JSF) also excel in reconnaissance and electronic eavesdropping. The aircrafts' combination of powerful phased array AESA radars, passive electromagnetic antennas and sensors embedded throughout their frames, powerful onboard computer processing, and secure high-bandwidth communications will give them capabilities once available only to dedicated electronic attack aircraft. DID has the full report.

Experiments also discovered that the F-35's AN/APG-81 AESA radar may also be able to function as a secure, ultra-high bandwidth communications link with other AESA-equipped aircraft (thus far, only American aircraft use AESA radars), allowing much more shared information than Link-16 or other current options could handle.

In FY/CY 2007, developments related to the overall program and to international partner participation include...

F-35 AA-1: first flight

(click to view full)April 9/07: The Pentagon releases its April 2007 Selected Acquisition Report, and the F-35 is one of the systems covered.

Overall, program costs rose 8.5% from $276.46 billion to $299.82 billion. The biggest culprit was the Pentagon's decision to decrese the annual buys and stretch the production schedule end from FY 2027 - FY 2034 (+$11.2 billion); accompanying that is a support increase due to aircraft configuration update, revised procurement profile, and methodology changes (+$6.42 billion). Commodity price increases for key structural materials like titanium was also an issue (+$5.47 billion).

Beyond that, increases due to revised assumptions based on contractor LRIP I proposals and methodology (+$8.3 billion) were offset by revised assumptions for prime and subcontractor labor rates (-$3.58 billion) and subcontractor costs (-$5.2 billion). Whether these changes will even out during the LRIP batches of F-35s, which already come with a much higher price tag than later production sets, was not discussed.

April 2/07: The US Government Accountability Office releases report #GAO-07-415: "Tactical Aircraft: DOD Needs a Joint and Integrated Investment Strategy." They are not optimistic re: current Pentagon plans for its future TacAir mix of F-22s, F-35s and F/A-18 Super Hornets.

March 22/07: The US military is trying to end the GE/Rolls Royce F136 engine program again in FY 2008, leaving Pratt & Whitney's F135 as the only engine option for the aircraft (see Feb 10/07 entry). The US Government Accountability Office is asked to examine the issue, and releases report #GAO-07-656T: "Analysis of Costs for the Joint Strike Fighter Engine Program." An excerpt:

"Continuing the alternate engine program for the Joint Strike Fighter would cost significantly more than a sole-source program but could, in the long run, reduce costs and bring other benefits. The current estimated life cycle cost for the JSF engine program under a sole-source scenario is $53.4 billion. To ensure competition by continuing to implement the JSF alternate engine program, an additional investment of $3.6 billion to $4.5 billion may be required. However, the associated competitive pressures from this strategy could result in savings equal to or exceeding that amount. The cost analysis we performed suggests that a savings of 10.3 to 12.3 percent would recoup that investment, and actual experience from past engine competitions suggests that it is reasonable to assume that competition on the JSF engine program could yield savings of at least that much. In addition, DOD-commissioned reports and other officials have said that nonfinancial benefits in terms of better engine performance and reliability, improved industrial base stability, and more responsive contractors are more likely outcomes under a competitive environment than under a sole-source strategy. DOD experience with other aircraft engine programs, including the F-16 fighter in the 1980s, has shown competitive pressures can generate financial benefits of up to 20 percent during the life cycle of an engine program and/or improved quality and other benefits. The potential for cost savings and performance improvements, along with the impact the engine program could have on the industrial base, underscores the importance and long-term implications of DOD decision making with regard to the final acquisition strategy solution."

March 15/07: The US Government Accountability Office issues a report on the F-35 program, which is well-described by its title: "Joint Strike Fighter: Progress Made and Challenges Remain" (#GAO-07-360). The strategy of buying aircraft before testing is complete was flagged as especially risky. See DID coverage & links.

Feb 27/07: Denmark becomes the 9th and final partner nation to sign up, as Minister of Defense Soren Gade signs the F-35 Production and Sustainment and Follow-on Development Memorandum of Understanding in Copenhagen, Denmark. Denmark joined the JSF program in 1997, and was the first European nation to enter the program's system design & development (SDD) phase in 2002. Danish companies have received SDD contracts for advanced composites, communications software, control-surface components, and weapons pylons. See Lockheed Martin release.

Feb 20/07: Controversy continues in Australia regarding the F-35, and has spread to include the 24 F-18 E/F Super Hornets the government is moving to buy as a stopgap until the F-35A arrives. See DID's coverage: "Australian Air Power Controversy: F-35 and Super Hornets Under Fire."

Feb 10/07: The option of interchangeable engines (P&W F100, GE F110) worked so well for the global F-16 and F-15 fleets that a similar approach became part of the F35 Lightning II program. In 2006, the Pentagon tried to cancel GE/Rolls Royce's F136 engine to save development dollars. High-level British protests and congressional opposition followed, and $340 million was restored to the F136 engine in the FY 2007 budget. Now Inside Defense reports that the FY 2008 budget submission cut all F136 funding again... can the F136 get itself resurrected again? Read DID's "The F136 Engine: More Lives Than Disco?" for more background.

Feb 8/07: F-35 Lightning II Faces Continued Dogfights in Norway. Endre Lunde chronicles developments in Norway, including endorsement of the rival JAS-39 Gripen by one of the governing coalition's political parties, and criticisms re: the F-35's fit for air patrol over Norway's long, over-water exclusive economic zone.

Feb 7/07: Defense Department And Italy Sign Joint Strike Fighter Agreement.

Jan 31/07: Norway formally signs the Production Phase MoU. See also Jan 23/07 entry.

Jan 25/07: Turkey signs the MoU for the F-35's production phase. Early estimates are that Turkey will want around 100 F-35As. During the session, Turkish Defense Minister Vecdi Gonul was asked about the Eurofighter (q.v. Nov 30/06 item). He replied that Turkey had decided to buy around 30 F-16 planes instead, a contract DID covered. Full story coverage at the above link.

Jan 23/07: Norway announces that it will participate in the F-35's production phase. Norway's Forsvardsdepartmentet has issued a release saying that Defence Minister Anne-Grete Strom-Erichsen has decided to sign the production phase agreement for the Joint Strike Fighter Program, owing to improvements in "industrial cooperation." On the other hand, the release takes pains to note that Norway plans to sign agreements with the Gripen and Eurofighter teams as well. See full DID coverage.

Dec 15/06: Lockheed Martin's release announces F-35 AA-1's successful first test flight, and provides details. This flight begins a 12,000-hour flight-test program. Defense-Aerospace, meanwhile, quibbles that the flags on the aircraft were mistakenly arrange back-to-front, instead of front-to-back.

Dec 12/06: Britain formally signs the F-35 Production Phase MoU. See UK MoD Release.

Dec 11/06: Anglosphere up. Tier 3 Partner Australia formally signs the production phase MoU, at a Pentagon ceremony that Canada and Britain also attended.

Dec 11/06: Tier 3 partner Canada formally signs the production phase MoU, and estimates up to $7 billion in industrial opportunities. In the Production, Sustainment and Follow-on Development Phase of the F-35 program, Canada's contribution is expected to exceed C$ 500 million (currently about $435 million) over 44 years. Thus far, 54 Canadian companies, universities and research institutions have won 154 contracts to date valued at approximately C$ 157 million (about $135 million).

While no commitment has been made yet re: replacing the current F-18 fleet with up to 80 F-35As, Canada is using its participation in the F-35 program to help define its future fighter requirements. See full DID coverage.

Nov 30/06: With Turkey's Defense Industry Executive Committee convening on December 12, 2006 to discuss the F-35 Lightning II's looming production MoU milestone (among other issues), Eurofighter officials said that the group has made Turkey an offer of its own for the estimated $10-12 billion fighter program. The consortium is offering Turkey "equal partnership with equal voting rights as other member nations" and a sliding scale of local work share depending on the number of fighters bought. The offer reportedly includes a $9 billion local work share with a 120 fighter buy, $6 billion with 80 aircraft, or $3.2 billion with a 40 aircraft purchase. See full DID coverage.

Nov 20/06: The GE/ Rolls-Royce F136 fighter engine team held a successful Preliminary Design Review (PDR), a three-month process led by the F-35 Program Office and Lockheed Martin and including Wright Patterson Air Force Base, the U.S. Air Force, the U.S. Navy, and defense officials representing the F-35 program's international participants. The PDR assesses the progress to the F136 design and its unique hardware, as well as the strategy to move the engine into a production phase later this decade. The event is a key milestone in the F136's $2.4 billion System Development and Demonstration (SDD) phase, launched in August 2005. The next major milestone is the Critical Design Review in late 2007. Thus far, GE says the F136 program is moving forward on-budget and on-schedule. See GE press release.

Nov 17/06: Inside the Navy reports that the Marine Corps wants to reverse course on a summer 2006 funding cut, in order to ensure the maiden flight of the short-takeoff variant takes place in FY 2008. Concerns about the F-35B vertical landing variant's technical maturity had prompted the Marines and Navy to propose a 14-month delay, removing 35-72 aircraft from the FY 2008-2013 spending plan (see Aug 22/06 entry). What changed? A recent program analysis and evaluation said the technical and schedule risk were within acceptable margins. With renewed confidence in the schedule comes renewed eagerness to keep the F-35B on track. If funding can be found as the Office of the Secretary of Defense finishes its FY 2008 defense budget proposal and attendant six-year spending plan.

Nov 14/06: The Netherlands' Secretary of Defense Cees Van der Knaap has signed the Production Sustainment & Follow On Development (PSFD) MoU in Washington D.C. together with his American counterpart, Deputy Secretary of Defense Gordon England. See the Ministerie Van Defensie release [Dutch], and the speech given during the signing ceremony [English]. With the help of our readers, DID also expands our coverage to include translations detailing the divergent Dutch political positions around the F-35 as their elections approach. Read "Dutch Sign F-35 Production MoU, But Political Challenges Remain."

F-35 JSF

(click to view full)Nov 13/06: Aviation Week's Aerospace Daily & Defense Report publishes "Rumsfeld's Ouster, Dems' Arrival Could Bring TACAIR Changes." There are a number of predictions that the changes will involve more F-22As, followed by fewer F-35s and more F/A-18 Super Hornets.

Nov 10/06: Australian Defence Minister Dr. Brendan Nelson announced that the Australian Government has given First Pass approval for the F-35 Joint Strike Fighter. The minister plans to sign the JSF Production Sustainment and Follow-on Development (PSFD) Memorandum of Understanding (MoU) in December 2006, once final administrative arrangements are in place. The decision has been strongly criticized in Australia, with concerns centering around its air superiority during the period from 2010 (when its F-111s receive early retirement) to operational capability with the F-35s around 2015-2018. See full DID coverage, and note also Nov 1/06 and Oct 2/06 entries, below.

Nov 6/06: EDO Corporation announces a contract from Lockheed Martin for the fabrication of precision, advanced-composite structures for the F-35 Lightning II. The contract calls for the delivery of components for 14 aircraft, and is valued at $1.8 million with delivery scheduled to be completed by December 2008. In addition to composite structures, EDO is developing pneumatic weapons-release systems and advanced antennas for the F-35s. See EDO press release.

Nov 1/06: AVM Criss: Does Groupthink Power Australia's JSF? Follow-on to DID's updated Oct 2/06 article. Retired Australian Air Vice Marshal Peter Criss pens a guest article, and discusses both the JSF decision and what he contends is a larger problem of groupthink within Australia's DoD.

Oct 31/06: News services in South Korea contend that they may be considering the F-35 Lightning II instead of their Phase 2 purchase of 20 F-15K Strike Eagles. DID looks into the reports, and concludes that the Lightning may fly in South Korean colors one day - but probably not as a 2007-2011 acquisition, given the program's timelines as noted above and the cost of low-rate initial production F-35s.

Oct 19/06: DID's article "Elec Tricks II: $9.7M for Further Research" is a follow-on to our earlier piece that cites the potential for the F-35's AN/APG-81 AESA radar to act as a secure, high-bandwidth communications relay (see section introduction). It seems the concept is being taken seriously, and given additional funding.

Oct 13/06: Pratt & Whitney's F135 jet engine has achieved Initial Flight Release from the F-35 Joint Program Office (JPO). This makes it eligible to power the F-35A flight test program, set to begin in late 2006.

Oct 11/06: The Dutch Court of Audit has issued its report on the F-35 project, covering subjects ranging from the auditing challenges on international programs to program cost and risks, to Dutch industrial participation. Its overall tone can be fairly described as cautionary, and it presents the F-35 as a risky investment. This could be significant given the November 22, 2006 elections, which are currently seen a a very close race for the current center-right coalition. DID has full coverage.

Oct 2/06: Recently-retired Australian Air Vice Marshal Peter Criss has puclicly broken ranks with Australia's DoD, and advocates buying the F-22A Raptors for Australia instead of early-production F-35As. DID has the coverage - including a very in-depth submission to a Parliamentary Committee that supports Criss' view and explains some of the thinking behind it. Follow-on additions include the position of the opposition Labour Party (buy F-22As initially, then consider the F-35 once it's in full-rate production), and adds links to formal submissions for Australia's DoD.

Note also our July 12/06 entry in this section; opposition in Australia is fueled in part by the country's expected buy of early-production aircraft, whose cost could be over $100 million each.

DID's coverage of CY/FY 2006 events and developments...

F-35 Program: System Development & Production

F-35B JSF Cutaway

(click to view full)DID is keeping this set of entries current from the 2006 to the present. Unless otherwise specified, contracts are issued by the US Naval Air Systems Command (NAVAIR) in Patuxent River, MD to Lockheed Martin Aeronautics Co. in Fort Worth, TX.

Feb 20/07: Fighter manufacturing affected by the position of the moon? Apparently. BAE is using new systems as part of Eurofighter manufacturing, and they've also been incorporated into F-35 production:

"To get round the problem BAE Systems has spent over GBP 2.5 million putting in special automated alignment facilities which use laser-trackers and computer-automated jacks. But what really ensures that each Typhoon's airframe is built as close to perfection as is humanly possible are the giant 'floating' concrete rafts on which the aircraft and measuring equipment sit...."

Feb 6/07: Northrop Grumman ISS International has signed a Letter of Intent (LOI) with Tusas Aerospace Industries, Inc. (TAI) to be a second source for the F-35 Lightning II center fuselage. TAI will produce a minimum of 400 center fuselages starting in the low rate initial production (LRIP) phase of the program. The LOI represents a potential value in excess of $3 billion in then-year dollars.

TAI had previously signed a $100 million, long-term agreement with Northrop Grumman in June 2005 to produce composite parts and sub-assemblies for the F-35 center fuselage, a component for which Northrop Grumman has primary responsibility. See Northrop Grumman release.

Jan 23/07: Norwegian firm Kongsberg announces almost NOK 2 billion (about $308 million) in "framework agreements" with Lockheed Martin and Northrop Grumman related to composite structure production for the F-35. That award could triple or quadruple over the F-35's lifetime - Kongsberg will have to invest in a new factory, and the whole agreement set is conditional on Norway choosing the F-35. Which is why the other yet-to-be satisfied condition is a guarantee from the Norwegian government to reimburse Kongsberg at some agreed-upon level if they choose another fighter. Those negotiations are ongoing. See full DID coverage.

July 17/06: United Technologies Corp. subsidiary Pratt and Whitney Military Engines in East Hartford, CT received a $10 million ceiling-priced modification to a previously awarded cost-plus-award-fee contract (N00019-02-C-3003) for preliminary design, program planning, and program management in support of F-135 jet engine gearbox redesign. Work will be performed in East Hartford, CT and is expected to be complete in January 2010. The F135 received Initial Flight Release certification in October 2006, and will power the F-35A's upcoming test flights.

July 17/06: United Technologies Corp. subsidiary Pratt and Whitney Military Engines in East Hartford, CT received a $12 million modification to a previously awarded cost-plus-award-fee contract to incorporate revised roll post bay ventilation changes into the F-135 propulsion system for the F-35B STOVL variant. These changes are required to meet revised system development and demonstration flight test roll post leakage requirements that were specified by Lockheed Martin, the F-35 air system prime contractor. Work will be performed in Bristol, England (75%), and East Hartford, CT (25%), and is expected to be complete in September 2008.

July 17/06: Pratt and Whitney Military Engines in East Hartford, CT received a $5.5 million modification to a previously awarded cost-plus-award-fee contract for the procurement of unique F-135 special test equipment required to perform F-135 engine ram air testing. Work will be performed in West Palm Beach, FL (95%), and East Hartford, CT (5%), and is expected to be complete in March 2007.

F-35A head-on

(click to view full)July 17/06: BAE announces that preparations for start of low-rate production of the F-35 Joint Strike Fighter (JSF) have started there with the award of a contract by the U.S. Department of Defense (see June 27/06 entry) and the company's JSF programme partner Lockheed Martin. The contract enables BAE Systems to begin procurement of high-demand materials such as titanium (note DID coverage re: titanium supply issues), and covers long-lead items for five F-35A aircraft, which make up the first of seven F-35 JSF Low Rate Initial Production (LRIP) batches. BAE is a production partner for the JSF airframe, as well as a number of subsidiary systems including its electronic warfare suite.

Under the current schedule, BAE Systems is expected to secure the full contract for the first production aircraft in the Q1 2007. Manufacturing for the first production aircraft is expected to start at the company's facility in Samlesbury, North West Enlgand in October 2007, and the first deliveries to partner Lockheed Martin's final assembly line in Fort Worth would occur in September 2008.

July 17/06: BAE Systems' describes its unique Thermo-Acoustic Facility (TAF) in Brough, East Yorkshire, UK, which measures the impact of extreme temperature and noise levels generated by the 40,000 pound thrust engine and lift fan of the F-35B Lightning II STOVL variant. BAE Systems simulates and measures the thermal and acoustic effects of aircraft landings on carrier decks using a scale model, full-scale temperatures and pressure from jet nozzles. Tests provide data in two significant areas: (1) how the heat and noise generated by the aircraft will affect carrier ground crew; and (2) the suitability of the materials needed for manufacture, due to heat transfer within the aircraft.

In addition, a full study of the configuration of the jet blast deflectors proposed for the UK's future Quuen Elizabeth Class carriers will begin toward the end of 2006 and continue into to 2007. This will complete the work of the Thermo-Acoustic Facility for the F-35 aircraft.

June 27/06:A $115.8 million modification to a previously awarded cost-plus-award-fee contract for integration of the British version of the joint strike fighter (F-35B JSF STOVL) with its CVF future carrier project, under the JSF systems development and demonstration effort. Work will be performed in Warton, United Kingdom (57%), Fort Worth, TX (35%), Orlando, FL (5%), and El Segundo, CA (3%), and is expected to be complete in October 2013.

April 28/06: A $901 million advance acquisition contract for long lead efforts and materials associated with the lot 1 low rate initial production of five F-35A Joint Strike Fighter conventional take-off and landing air systems for the US Air Force. Work will be performed in Fort Worth, TX (60%); El Segundo, CA (25%); and Samlesbury, United Kingdom (15%), and is expected to be complete in January 2010. This contract was not competitively procured (N00019-06-C-0291).

April 28/06: A $52.4 million ceiling-priced modification to a previously awarded cost-plus-award-fee contract (N00019-02-C-3002). It exercises an option to certify the GBU-39 Small Diameter Bomb for the U. S. Air Force Joint Strike Fighter conventional take off and landing (CTOL) aircraft, and also eliminates the effort to certify the F-35A for wind corrected munitions dispenser (WCMD) GPS-guided cluster bombs, and for external fuel tanks. Work will be performed in Ft. Worth, TX (89%); El Segundo, CA (6%); Orlando, FL (3%); and Wharton, United Kingdom (2%), and is expected to be completed in October 2013.

F-35 Program: Ancillary and Sub-contracts

The 737 'JSF CAT-Bird'

(click to view whole)Jan 23/07: Vision Systems International, LLC in San Jose, CA (VSI) announces that their Helmet Mounted Display System (HMDS) recently flew for the first time on an F-35 Joint Strike Fighter aircraft. The release adds that:

"The HMDS has been in development for five years and recently completed all required safety of flight tests, allowing in-flight seat ejections up to 450 KEAS (knots equivalent air speed). It has demonstrated structural integrity to 600 KEAS as a critical risk mitigation step towards full flight certification."

Jan 23/07: The Joint Strike Fighter Cooperative Avionics Test Bed (CATB), a 737-300 aircraft extensively modified by BAE Systems, successfully completed its maiden flight at Mojave, CA, following an effort that as lasted nearly 3 years. The "CAT-Bird," is a flying test bed that replicates the F-35 avionics suite; among other things, it will be used to verify "sensor fusion" - the F-35's capability to collect data from multiple sensors and fuse it into a coherent situational awareness display.

Creating the CAT-Bird was no minor task. Structural modifications include the addition of a nose extension to simulate the F-35, a 42-foot-long spine on the top, a 10-foot "canoe" on the bottom to accommodate electronic equipment, and twin 12-foot sensor wings that replicate the leading edge of the F-35's wings. The inside of the plane also was transformed. An F-35 cockpit will allow the sensor inputs to be displayed as they would be in the fighter itself, while rest of the interior houses equipment racks for the avionics equipment, plus 20 workstations for technicians to assess the performance of the avionics. See BAE release.

Dec 16/06: Engine testing isn't cheap. A USAF article puts some numbers beside the role Arnold Engineering Development Center will play in F-35 engine testing. Jeff Albro, AEDC's program manager for the Pratt & Whitney F135 turbine engine, has said that:

"We spent about $17 million on facilities upgrades.... Most of it was specifically and uniquely required for the JSF engine -- things other legacy programs haven't had to have before." Engine test program costs here, ranging from facility upgrades that began here in 2001, through Operational Capability Release, are nearly $200 million according to Albro.

Nov 16/06: BAE Systems is using a new high-precision machining tool from StarragHeckert of Switzerland at the Company's F-35 site in Samlesbury, UK. The new 5-axis machine immediately went into production, machining a titanium component that will sit in the F-35's aft fuselage. A second 5-axis StarragHeckert machine is scheduled for installation by the end of the year. Machining metals like titanium is very difficult, especially at the precision levels required in a plane like the F-35. See also DID's Nov 17/05 coverage re: titanium machining innovations by Stork NV and their resulting contract from Pratt & Whitney for engine components.

Tom Fillingham, BAE Systems managing director, F-35 Lightning II said: "Although we are still in the System Development & Demonstration (SDD) phase, which will see us deliver 23 aircraft over the next 3 years, we are already working to a schedule that requires a new aircraft to start assembly every 4 weeks – a rate which is more akin to production phases of a programme... As we are increasing the rate at which we start to assemble the aircraft, BAE Systems and the supply chain have to supply more components, hence we need additional capability and capacity."

July 19/06: Jane's reports that BAE Systems has signed letters of intent worth around $1 billion relating to low-rate initial production of the F-35 with a series of second-tier suppliers in Denmark ($250 million, Terma for F-35B horizontal tails), Canada ($150 million; Avcorp for F-35C outboard wing work and Magellan for F-35A horizontal tails), and Australia ($600 million; Broens, Marand and Metaltec for rate tooling services and Hawker De Havilland for F-35A vertical fins). See also BAE Release.

June 23/06: This US Air Force article describes testing underway to help define the interface for the HMDS helmet-mounted display. Another key challenge is clearing the heavier HMDS helmets for ejection at high speed, without creating fatigue or safety problems for smaller pilots. The Elbit/ Rockwell-Collins joint venture Vision Systems International, LLC (VSI) will supply the HMDS to all US and international customers.

June 6/06: Lockheed Martin has selected Terma A/S, Grenaa to supply conventional edges for the F-35 Joint Strike Fighter family's high-tech carbon-fiber horizontal stabilizers. Terma won the selection in international competition on a best value basis, and the project represents a potential turnover value of approximately US$ 50 million. See DID's coverage for a list of other JSF contracts Terma firms have won.

May 12/06: The Dutch firm Stork Aerospace continues to do very well indeed in the JSF's best-value competitions. Its latest sub-contract for titanium/composite flaperons could be worth up to $170 million, bringing its potential total of JSF-related sub-contracts to over $500 million. DID explains what the heck a "flaperon" is, and lists and links to Stork's other JSF-related work.

March 3/06: Melbourne-based family company Production Parts won what is potentially Australia's biggest-ever military aircraft engine parts deal: an agreement to supply high-pressure turbine supports for the JSF's Pratt & Whitney F135 engine. Production Parts was also chosen in 2004 to produce a titanium bearing housing for the fighter, and the two deals bring the potential value of the overall work to more than $60 million (A$ 80 million) over the life of the JSF project. Australian industry took a different and interesting approach to the subcontractor compeition process... see DID's article for more.

JSF HMDS

(click to view full)Feb 21/06: The Elbit/ Rockwell-Collins joint venture Vision Systems International, LLC (VSI) has been selected to supply the JSF Helmet Mounted Display System (HMDS) to all domestic and international F-35 customers, replacing conventional heads-up displays mounted in the aircraft. They also received a new $156 million contract that expands the company's effort to include provision of pilot flight gear, including the oxygen mask and chemical/ biological hazard protection. See DID article: VSI Gets $156m Expansion on F-35 Helmet Displays Contract

Feb 16/06: P&W, Rolls Royce Define Cooperation on F135 Jet Engine. Rolls Royce is a major partner with GE in the F136 alternative engine, which the Pentagon has slated for the chopping block in its 2007 budget request. Britain and Rolls Royce aren't happy, and it remains to be seen whether the cut will pass.

Feb 9/06: Despite the threat of cancellation, Testing has resumed on the GE/RR F136 engine under the $2.4B System Design and Demonstration contract that was awarded in August of 2005.

Jan 4/06: Will the F-35 program be cut to one engine option, creating a winner-take-all for Pratt & Whitney? See DID - Reports: Cuts on the way to F-35 JSF R&D, Engine Programs, which also discusses positive past experiences with the F-16 and F-15's choice of F100 and F110 engine options.

Dec 7/05: ManTech International Corporation has been awarded a contract from the U.S. Air Force to provide security services to the F-35 Joint Strike Fighter (JSF) program. The competitively awarded contract is for one year with four option years, and has a total potential value to ManTech of $27.5 million. See DID coverage.

Nov 18/05: L-3 Wins F-35 JSF Panoramic Cockpit Display Contract Worth up to $200 million. See DID coverage.

Nov 17/05: Stork Aerospace N.V. of the Netherlands and U.S. firm Pratt & Whitney announce an agreement for the production development of P&W F135 jet engine componments. This agreement involves new High Performance Machining (HPM) technology for titanium components, and represents a breakthrough in titanium machining as an advanced and efficient production technology for aircraft jet engines. See DID's full coverage, explaining the award's significance.

Sept 30/05: Lockheed Martin Aeronautics Co. in Fort Worth, TX received a $13.7 million modification to a previously awarded cost-plus-award-fee contract (N00019-02-C-3002) for procurement of one large capacity fiber placement machine in support of the Joint Strike Fighter program. This modification will include delivery and installation of the fiber placement machine, and training of personnel in the machine's operation, maintenance and any other associated training. Work will be performed in Foggia, Italy (70%) and Fort Worth, TX (30%) and is expected to be complete in September 2009.

Addtional Readings & Sources

DID FOCUS Article - F-35 Joint Strike Fighter: SDD Contracts & Events FY 2006.

F-35 Joint Strike Fighter Program site. For other news that includes testing results and other areas not covered by contracts, see the news section.

Lockheed Martin - F-35 Lightning II. Includes sections covering topics such as Earned Value Management, testing, partnerships, manufacturing, et. al.

Air Force Technology - JSF (F35) Joint Strike Fighter, International

Aerospaceweb - F-35 JSF Weapon Carriage Capacity. Good discussion of the 3 versions and their specific limiting factors.

UK Parliamentary Defence Committee. An important source of information re: Tier 1 partner Britain's future participation in the F-35 program.

Anthony G Williams - Will The Fighter Gun Survive? Looks at the case for having guns on aircraft, then looks at the performance of various systems around the world. Both Boeing & Lockheed Martin originally specified the Mauser 27mm cannon for the F-35. The program later changed to the American GAU-12 rotary that equips the AV-8B Harrier, and is now being phased out of use on the AC-130 Specter fleet.

Flight International (June 28/06) - First Strike: Flight International JSF Special. A very informative tour of F-35 production and key decisions to be made. Articles include "The Mating Game," describing key wing-fuselage changes to save weight, and "Who Will Be Building JSF" which discusses the international production arrangements and issues.

DID (May 11/06) - Norway Remains in F-35's SDD Program But Evaluates Other Aircraft. DID lists the official competitors. See also Norwegian reader Endre Lunde's in-depth guest article "Norway's Future Fighter Competition: A Norwegian View."

DID (March 10/06) - F-35 Joint Strike Fighter Program: UK Update. Britain has its Plan B if the JSF doesn't work out... France's Rafale.

DID (March 3/06) - Norway to Back out of F-35 JSF Over Industrial Share?

DID (Aug 24/05) - $3.43B for F-35 JSF Engine Development. DID notes major contracts for development of the JSF's F135 and F136 engines, and talks about their respective competitive strategies and progress.

Source : Defence Industry Daily (Defense News)

MILITARY PURCHASING NEWS FOR DEFENSE PROCUREMENT MANAGERS AND CONTRACTORS

(http://www.defenseindustrydaily.com)

Posted 18-Apr-2007

Photo : http://www.defenseindustrydaily.com

(20.04.2007)

|